I use 80m on occasion, and I think I have enough room in the garden to accommodate a 40-10m EFHW with an 80m addition, so after watching a few YT videos I thought I'd have a go.

I ordered up a piece of 40mm PVC pipe, a reel of 0.6mm magnet wire and other fittings plus some heat shrink.

I drilled two holes in the PVC pipe, one for the mounting post and one for the magnet wire, and after doing some online calculators, wound 62 turns of wire round the pipe.

Feeling good, I cut the end and measured with an LCR meter. 109µH. I was happy enough with that!

I soldered on the tags and wrapped the pipe in marine-grade dual layer adhesive-lined heatshrink. I mounted the posts and the tags, and realised that I'd ordered the wrong size marine-grade stainless steel nuts. Or the wrong size bolts. Either way...

So I have temporarily used what I had to hand to keep it all secured.

I'll be building the antenna at the weekend, asusming the nuts arrive in time.

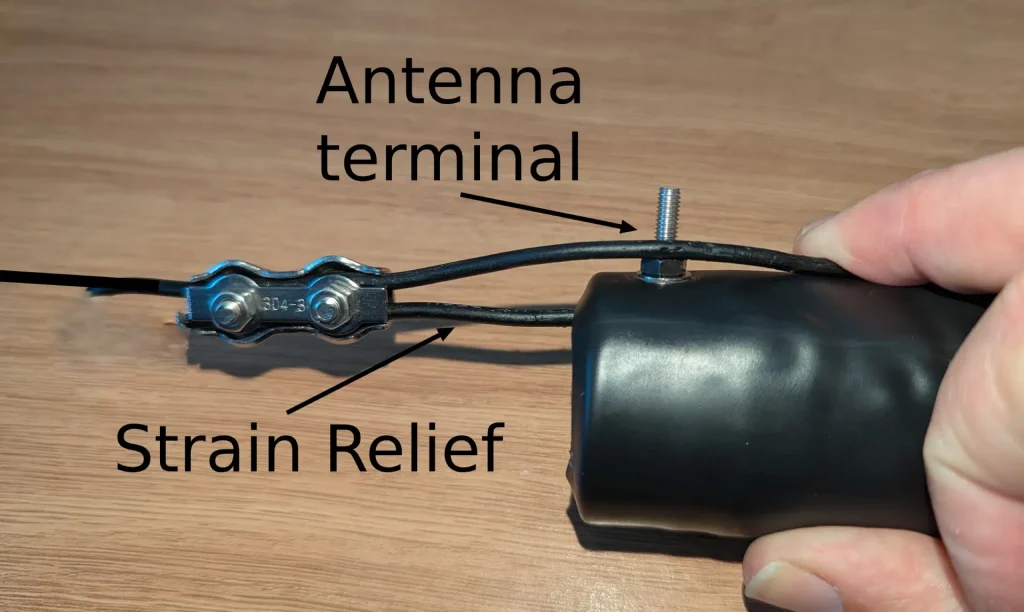

One thing I don't really see on other makes is how people mount and deal with strain relief. My thinking is to solder the antenna wire to ring connectors and mount them on the posts, then pass an old leftover piece of dipoflex through the middle of the coil and connect it to the antenna wire each side with cable clamps, so that the antenna line is not taking any strain, kind of like this:

When together, the inductance has changed to ~110µH, so happy with that!

The final step was to put some liquid electrical tape on the connectors in the pipe.

I mounted the coil and trimmed a tail down to around 1.6m, and I hit a sharp dip to 1.2:1 vSWR at 3.7MHz.